Click the “Play” arrow to see the vicious attacks on some of our city assets. This brutal fight can be hazardous and potentially fatal for utility workers. CAP eliminates unsafe practices and reestablishes the peace.

Disclaimer: May not represent the performance of all traditional materials, manufacturers, processes, treatments, installations, system types, geographic locations, practices or other conditions.

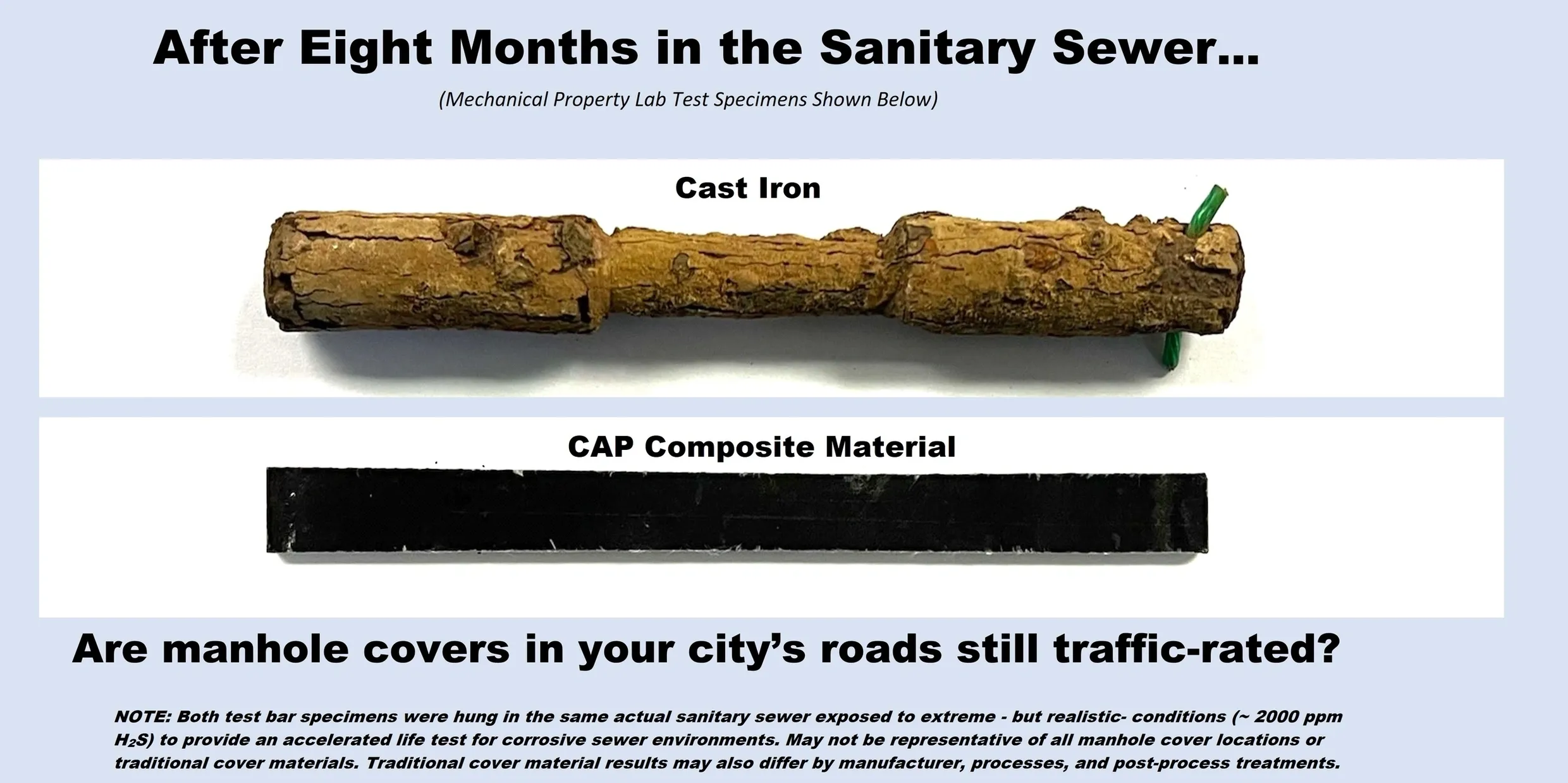

CAP Resists Corrosion without Expensive Coatings

Corrosion in Wastewater and Grease Traps

Some sewer lids corrode from Hydrogen Sulfide gas exposure, water, and salt, which can lead to cover failure in harsh environments. Improvements in stormwater infiltration prevention have made sewage less dilute and H2S more concentrated. Fats, Oils, and Grease (FOG) in grease traps also contribute to severe H2S production. H2S is converted to sulfuric acid by bacteria in the sewer system.

Corrosion Costs the US Infrastructure…”Big League”

“…the total annual estimated direct cost of corrosion in the U.S. is a staggering $276 billion” Source: “Corrosion Costs and Preventive Strategies in the United States,” U.S. Federal Highway Administration (FHWA), PUBLICATION NO. FHWA-RD-01-156

See Report Summary by National Association of Corrosion Engineers

H-20 Strength…CAP resists corrosion

In specific wastewater treatment and collection locations with high H2S concentrations (e.g. lift stations, treatment plants, grease traps, air release valves), CAPs can help maintain that critical H-20 proof load certification. CAP stay strong even after exposure to caustic environments.

CAP Extends Product Life in Highly Corrosive Sewers

In sewer systems with high H2S levels, some iron covers can corrode within one year. But cities do not audit manhole covers for traffic strengths after installation. Maybe they should?

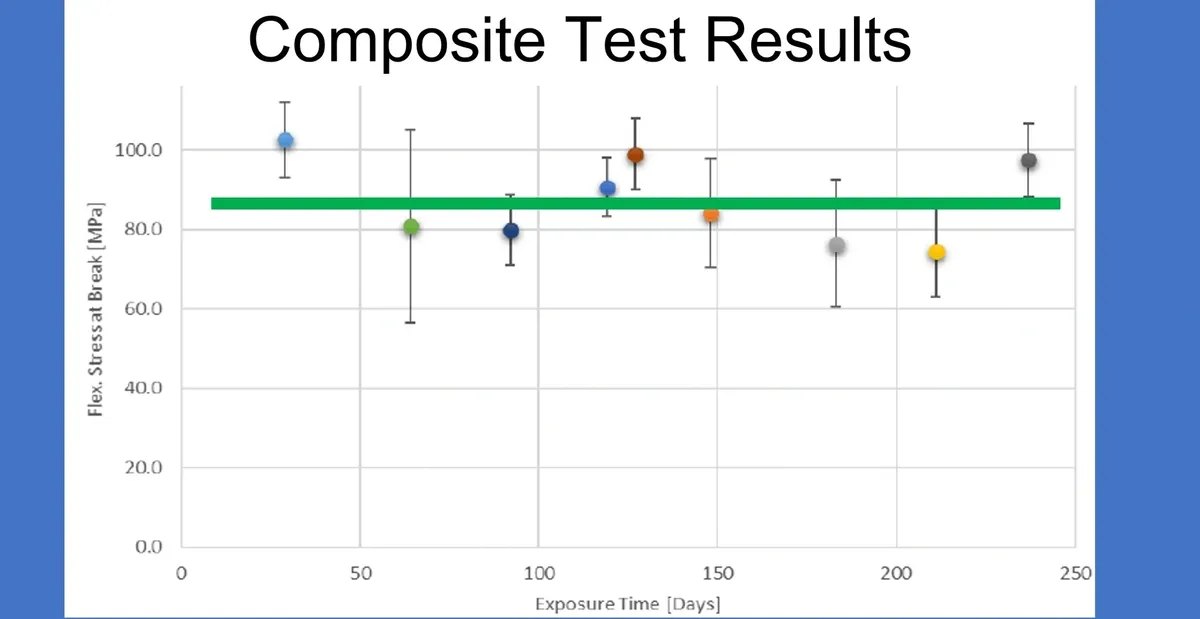

CAP Composites Do Not Degrade from H2S Corrosion

Zero Strength Loss!!

University of Texas RGV researchers exposed test bars to extreme levels of H2S in a manhole (2000 ppm). The CAP material did not weaken after 8 months. 2000 ppm is a very high concentration, but it does exist in some actual US manholes.

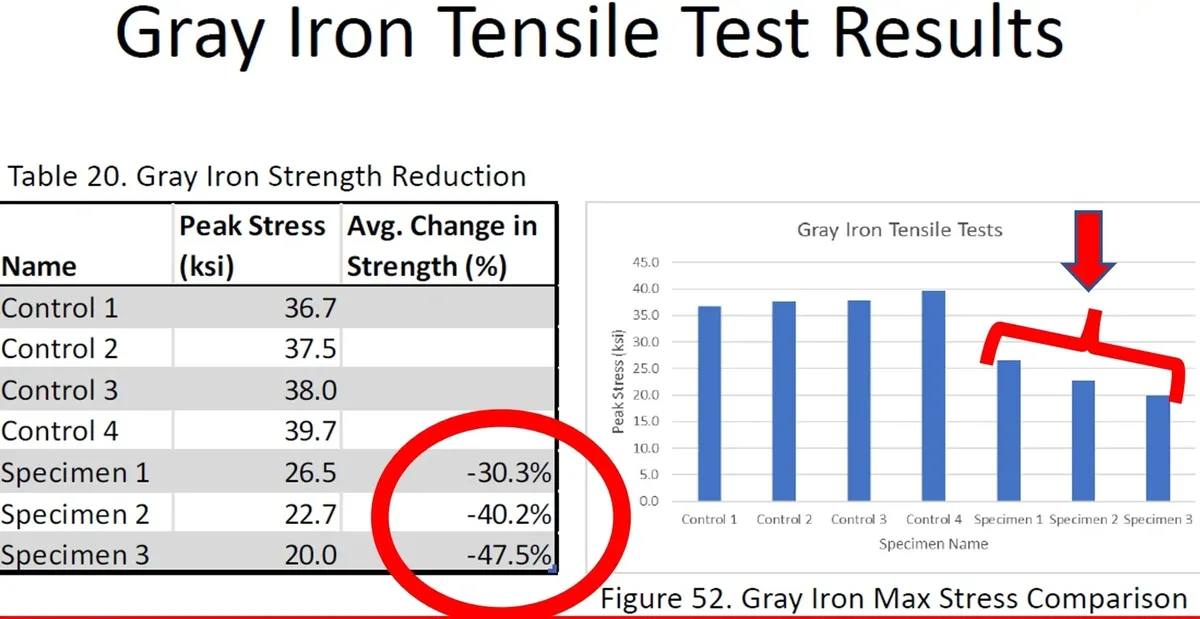

Iron weakened 30%-50% in 8 months!!!

In this same manhole, UTRGV engineers found that the grey iron test bars lost almost half of their strength after being exposed for 8 months. Results may not reflect all iron manufacturers with various supply sources, processes, treatments, etc.

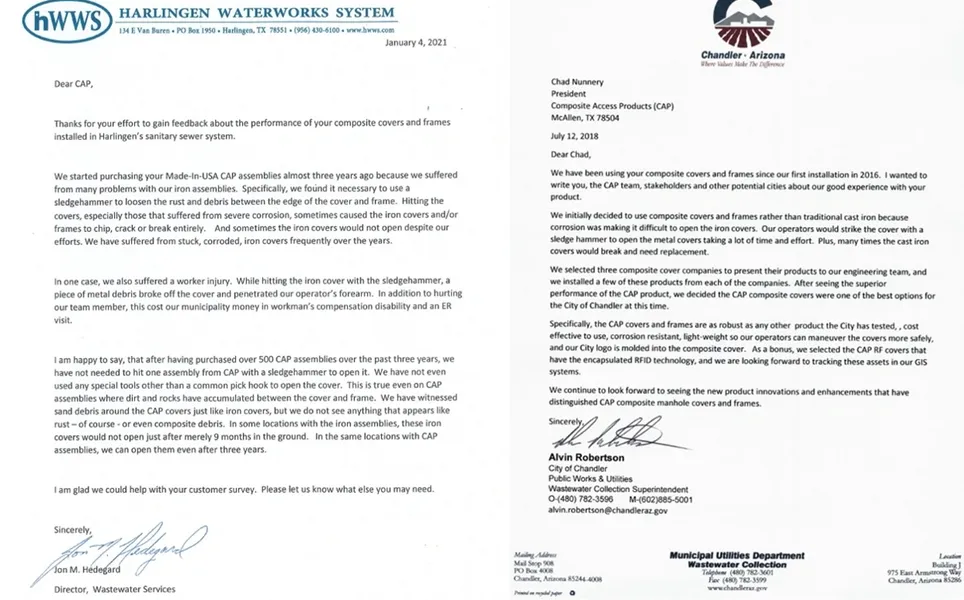

Municipalities Report Zero Sticking Problems with CAP

It’s Hammer Time!

CAP Composites Resist Sticking…Even In Areas with Dirt, Rocks, and Debris Accumulation

Municipalities love CAP assemblies….

“We suffered from stuck…covers frequently.” “We found it necessary to use a sledgehammer to loosen the rust and debris between the edge of the cover and frame.”

Then, “after having purchased over 500 CAP assemblies over the past three years, we have not needed to hit one…not used any special tools…even where dirt and rocks have accumulated between the cover and frame.”

-Jon Hedegard, Director Wastewater Services

Harlingen Waterworks Systems, TX

CAP – “Superior Performance”

The cover in this extreme case would not separate from the frame even after cracking and chipping with a sledgehammer. The municipality had to excavate the entire assembly from the ground and replace it.

CAP – “Superior Performance”

“Our operators would strike the cover with a sledgehammer…covers would break and need replacement.”

Then, “After seeing the superior performance of the CAP product, we decided the CAP composite covers were one of the best options for the City of Chandler at this time.”

Alvin Roberston, Superintendent

City of Chandler, AZ

CAP Frames Prevent Corrosion Below The Cover

CAP Frames – Support Where You Need It

During a replacement, city workers observed that this traditional cover support on the frame had entirely corroded away revealing why it was “sinking.”

CAPs Assemblies Don’t Fall on the Job

When some frames corrode – material flakes off from the frame decreasing support to the cover. After material loss from the cover and frame simultaneously, the result is predictable.

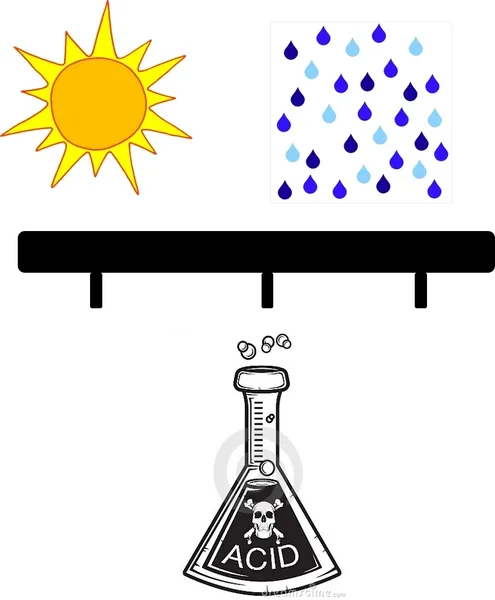

Durability – Not Just UV Exposure!

Many inquire about the weather resistance while ignoring the more frequent reason for replacements – acid exposure under the cover.

Corrosion Affects the Frame and Concrete Below

In some extreme locations, corrosion is so aggressive that remnants of the oxidized iron are left on the concrete below the frame.

CAP Prevents Water Pathways From Metal Loss Due to Corrosion

No Corroded Holes and Gaps with CAP!

Inflow of rainwater into sanitary sewer systems comes from many sections of the collection system. Holes and gaps in the cover and frame assembly will increase the gallons-per-minute inflow of rainwater, especially in flood situations. CAPs help eliminate this source of inflow.

Whole Above the Hole

CAPs corrosion resistance will help keep your covers intact, resisting inflow. Corrosion holes permit flow.

CAP Avoid Corrosion Fractures-Half a Cover Won’t Stop Inflow

CAPs won’t crack from corrosion. Mechanical strength degradation on some covers can cause fractures.

Hydrogen Sulfide Gas? No Problem for Composites!

The material used in CAP’s covers is also selected to use in frames and hangers in the electrowinning cathode/anode reaction. In this copper purification process, copper sheets are held with composite supports inside a sulfuric acid tank. While the acidic vapor eats through most materials, CAP materials resist the high concentrations of sulfuric acid vapor exposure.

Durability-both sides of the cover? Just CAP that! ®