CAP™

Composite Manhole Covers &

Frames

US Manufacturer of Composite Covers and Frames

Winner 2020, Finalist 2023 – Award for Composites Excellence (ACE)

US Manufacturer of Composite Covers and Frames

Winner 2020, Finalist 2023 – Award for Composites Excellence (ACE)

(844) 344-CAP1 (2271) or

CAP’s composite cover technology was selected for a PBS educational broadcast. Hosted by Dennis Quaid, this high-quality production showcases the benefits with interviews from Public Works leaders from Fulton County, GA, and McAllen, TX, including how CAPs can eliminate a leading cause of water pollution. Click “Play” to see the video.

(Not an endorsement by Dennis Quaid or Any Other Participant)

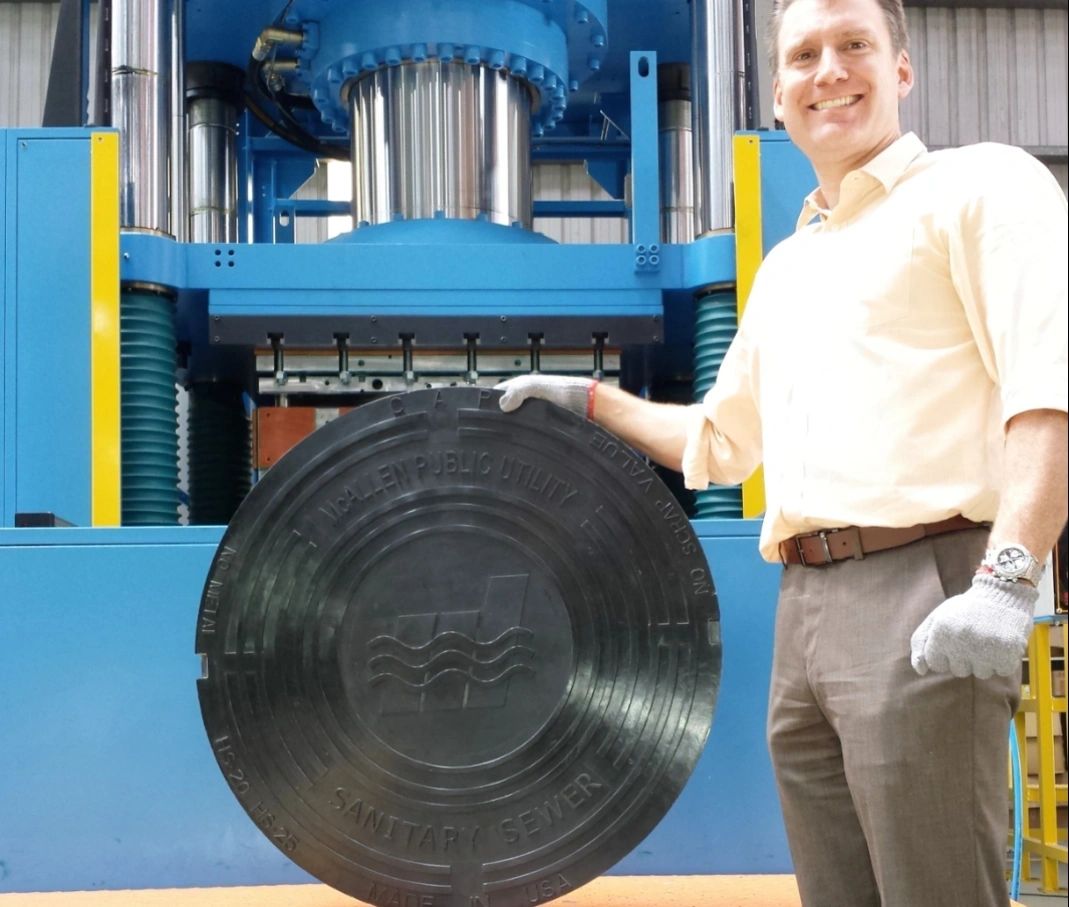

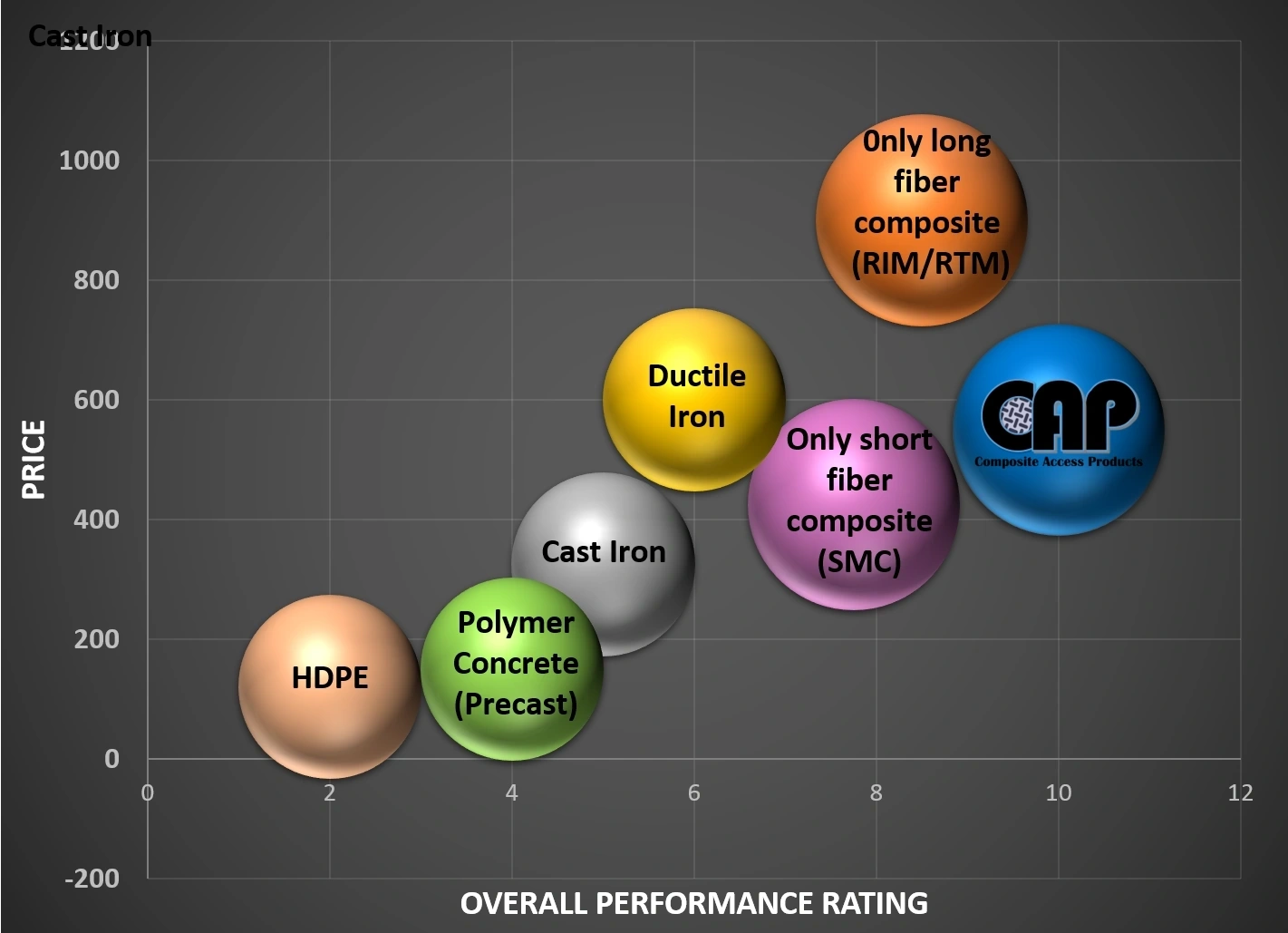

Composite Access Products (CAP) manufactures composite covers and frames with compression molding. Unlike other composite options (RIM/RTM/SMC), CAP’s use a unique proprietary combination of continuous/long and short fibers for both load AND surface strength. CAP covers passing the AASHTO M 306 Proof Load test requirements for American highways with the rating of HS-25. CAP is the only US manufacturer to mold in-house – rather than outsource or import – a composite manhole cover with a state DOT approval letter for use “within roadway.” And… no speed limit restriction!

CAPs are Made In The USA and proudly announce it. If “Made In USA” is not clearly on the cover top then the cover is not American -most likely Chinese. Have you audited suppliers and their suppliers-complying with the new Uyghur Forced Labor Prevention Act (UFLPA)? Complying to Build America Buy America Act (BABA)? Country of Origin laws (19 U.S. Code § 1304 (e)? Where is your municipality putting US tax dollars?

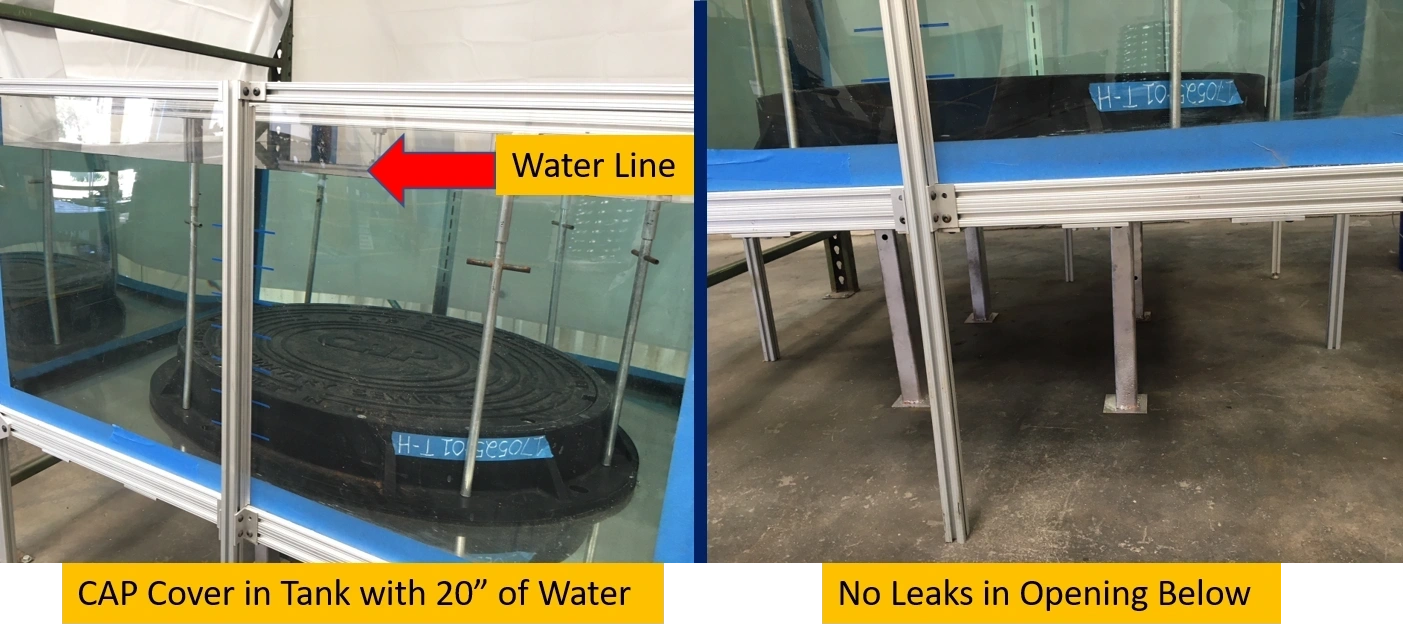

CAP’s composite cover and frame mate precisely, are gasketed, and bolted for optimum seal. And because CAPs do not corrode or stick, this tight fit won’t cause an opening problem. Third-party validated by a major US utility, CAP has the “best by far” watertight cover.

CAP covers prevent corrosion, which weakens and can contribute to stuck covers.

Precisely mated composite covers and frames stop inflow and reduces sewer overflows. A new solution to fight water pollution

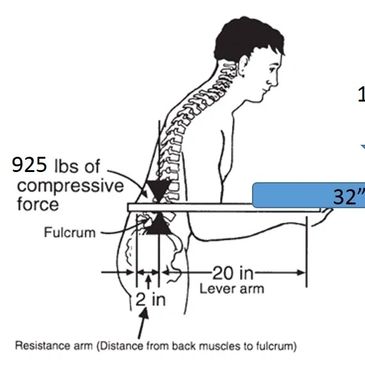

CAP covers weigh approximately half traditional manhole covers. Reduce back injuries with CAP.

Protect pedestrian safety and potential liability from falls into open manholes. No reason for thieves to steal CAPs.

Transmission requires antenna holes in traditional covers. Signals pass through CAPs from underneath. Holes & shields – unnecessary.

Pigmented covers and the CAP STONE call attention from da istance, enhance cosmetic appeal, and help match pavers.

CAP eliminates the root cause of manhole cover theft: the scrap metal content.

Heavy covers reach weight limits of trucks before volume limits – thus lighter covers reduce shipments

Composites insulate pets and people unlike rapid electric/heat conductivity.

Learn more about some of the solutions offered by the CAP products compiled and explained in this video. Each above icon has its own specific page as well, and you can “click” the image to read more information about each CAP benefit. Click the “Play” arrow to see the video.

The initial price is not the true cost to municipalities. For the real cost assign a value for each CAP savings and allocate over your annual cover purchases.