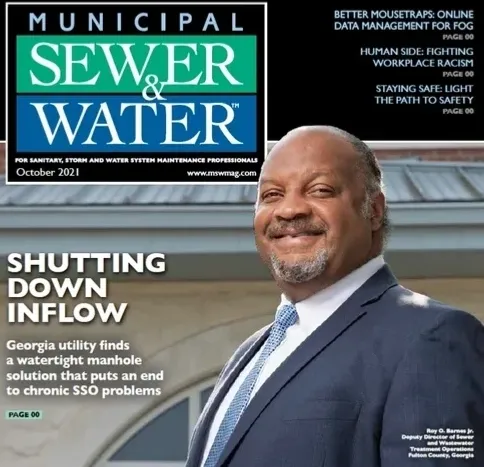

“It was the first time in the history of the county that we reported no spills.” (from article – MSW, Oct ’21)

” Thanks {CAP}. You have been key to our success. Great product.” (LinkedIn comment, Sept. ’21)

Roy Barnes, Deputy Director of Public Works – Fulton County,

“CAP has created a great product and provides quality jobs in the RGV; this was an easy decision.” LinkedIn comment, Sept. ’21

Jeff Underwood, City Manager, City of Alton, TX

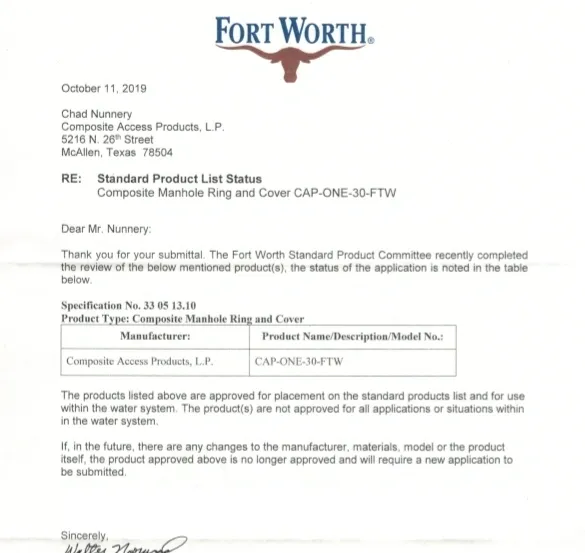

Fort Worth, TX Approves CAP!

Fort Worth Improves Safety and Reduces Theft

CAP helped solve two problems that plagued Fort Worth: 1) Safety concerns about lifting heavy iron covers, 2) Theft of manhole covers for scrap content. CAP solves both these issues. CAPs are half the weight which reduce back, toe and finger injuries – thus workman’s comp costs. Also, CAPs elminate the root cause of theft – scrap iron. There is no market for composite scrap so thieves will not be rewarded. This eliminates manholes without covers which are hazardous to ourselves, our children, and our vehicles.

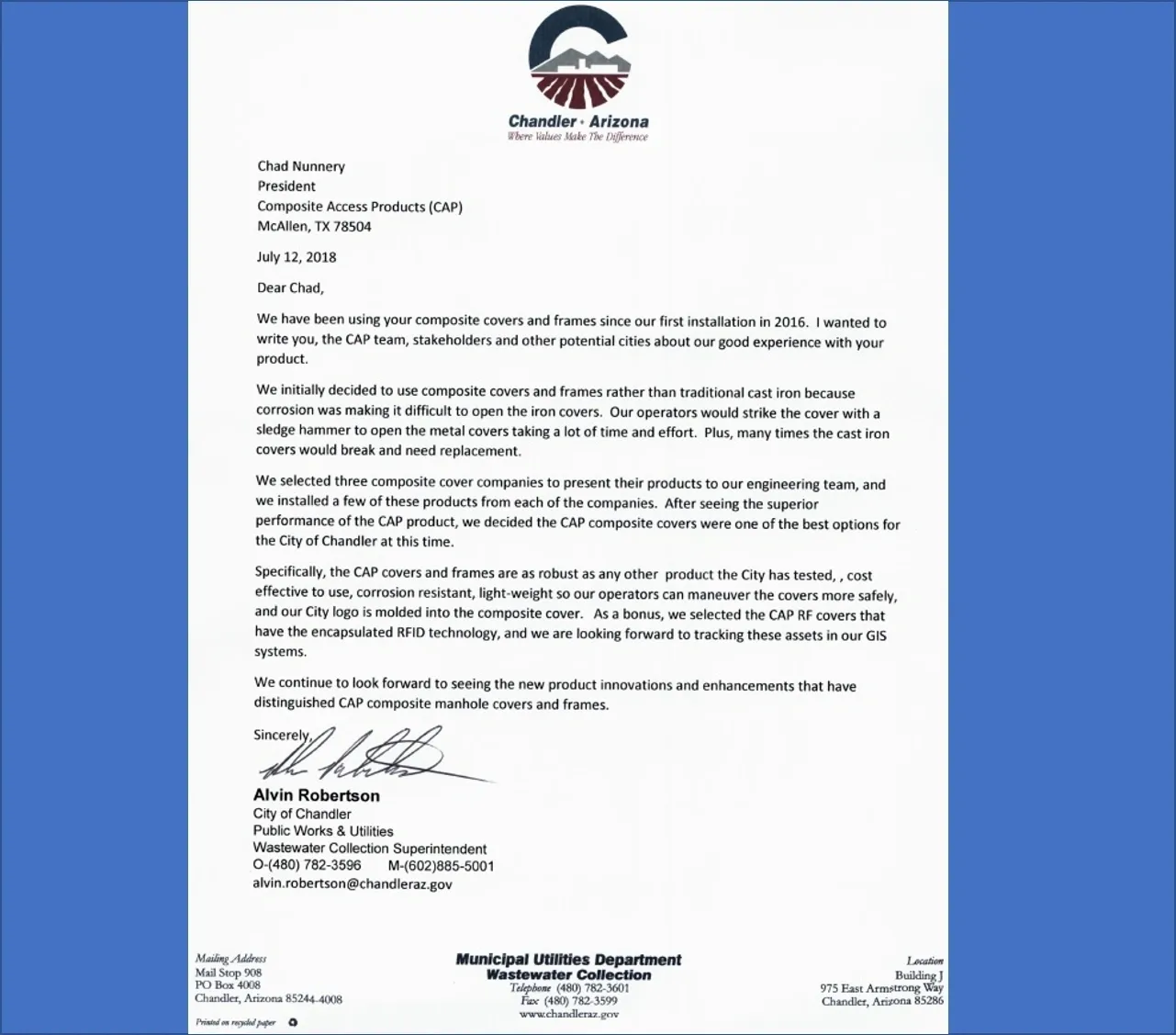

CAP Wins Chandler Challenge! Selected as Top of Class.

Composites Selected To Solve Stuck Covers

The city could not open many covers – frequently stuck covers convinced the city to go to composites.

Chandler Compares Composite Options

In a comprehensive review of four different composite options, Chandler engineers reveal quality differences.

CAP selected after intense review!

CAP covers were chosen among all the composites presented and continue to satisfy Chandler today.

MRRSA Chooses CAP to Beautify Streets

Vibrant, Elegant, Forceful

Jumping off distinct CAP composite media: tactility & texture reminiscent of the expressionistic brushstroke. The Manasquan River Regional Sewerage Authority (MRRSA), NJ utility will prevent sewer spillovers with watertight CAPs, and nurture aquatic populations like their treasured sea run brown trout.

Happy to Have These New Customers Use CAP

Irving, TX

Waco, TX

Indianola, IA

Sanford, FL

Gainesville, FL

Duckett Creek, MO

San Antonio, TX

North Port, FL

Ocala, FL

Fort Worth, TX

Apopka, FL

Blue Wave Carwash

Huntsville, TX

Fort Bliss – El Paso, TX

Allen, TX

Flagstaff, AZ

Queen Creek, AZ

Melbourne, FL

CAP Covers Easily Surpass the American Traffic Standard

… With “Flying Colors” (Dr. Robert Jones, University of Texas, RGV)

The American Association of State Highway and Transportation Officials (AASHTO) designates the Standard Specification for Drainage, Sewer, Utility, and Related Castings – M 306-10. Section 6 of this standard details the Proof-Load Testing.

Almost zero permanent deformation!

“H-20” and “H-25” certification methods use 40,000 lb and 50,000 lb loads, respectively, on a 9×9 platen for 1 minute. After releasing, permanent deformation cannot exceed 0.125 inches. CAP’s cover with a 32-inch span deformed less than 0.02 inches after a 50,000 lb load (H-25).

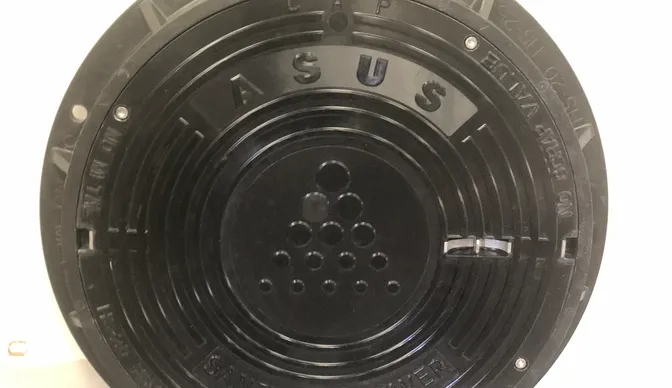

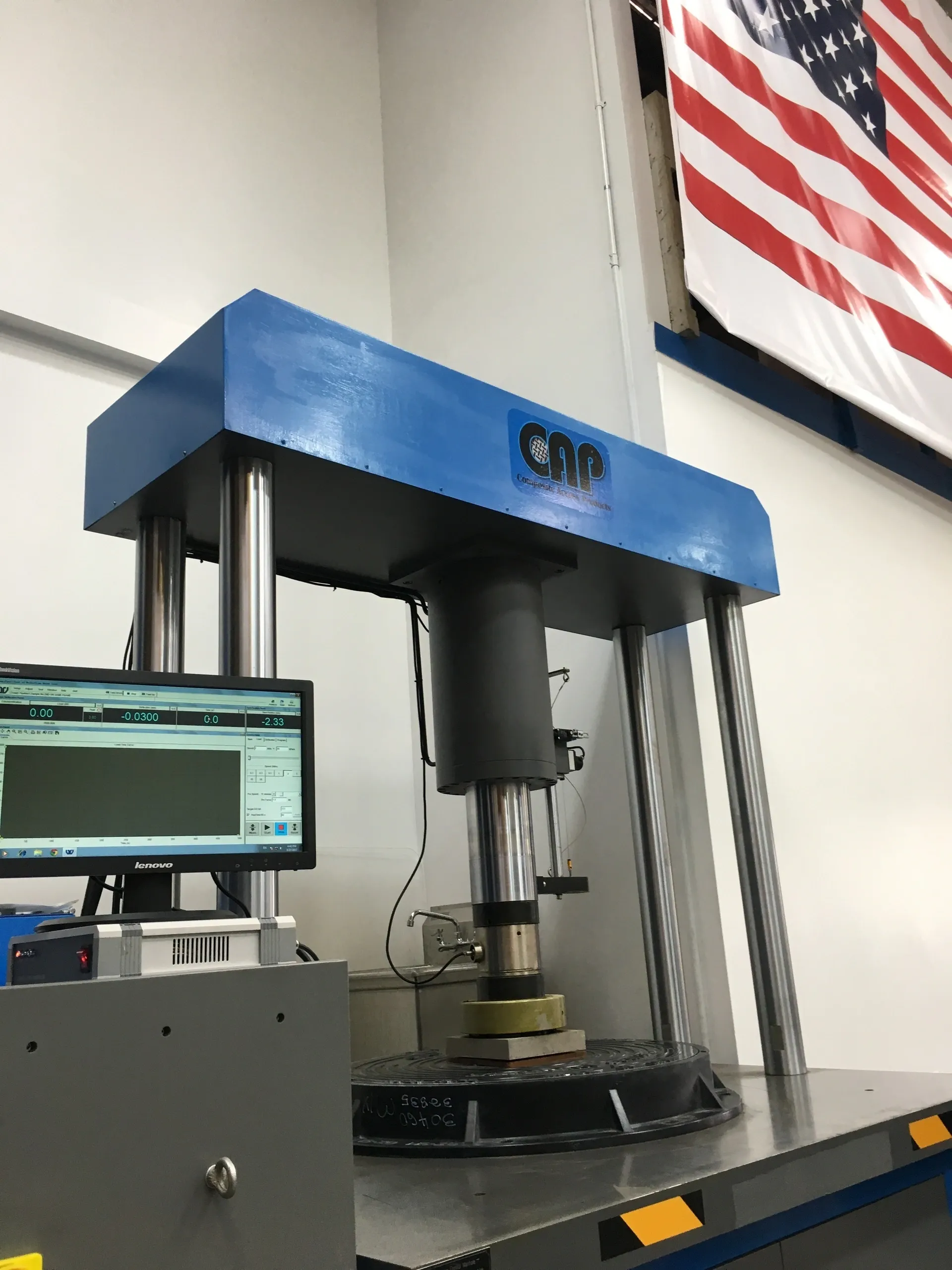

CAP Has Internal Proof Load Testing Capabilities (photo)

While our certification testing is with a third-party laboratory, CAP has the capability to test in-house for development and quality inspections.

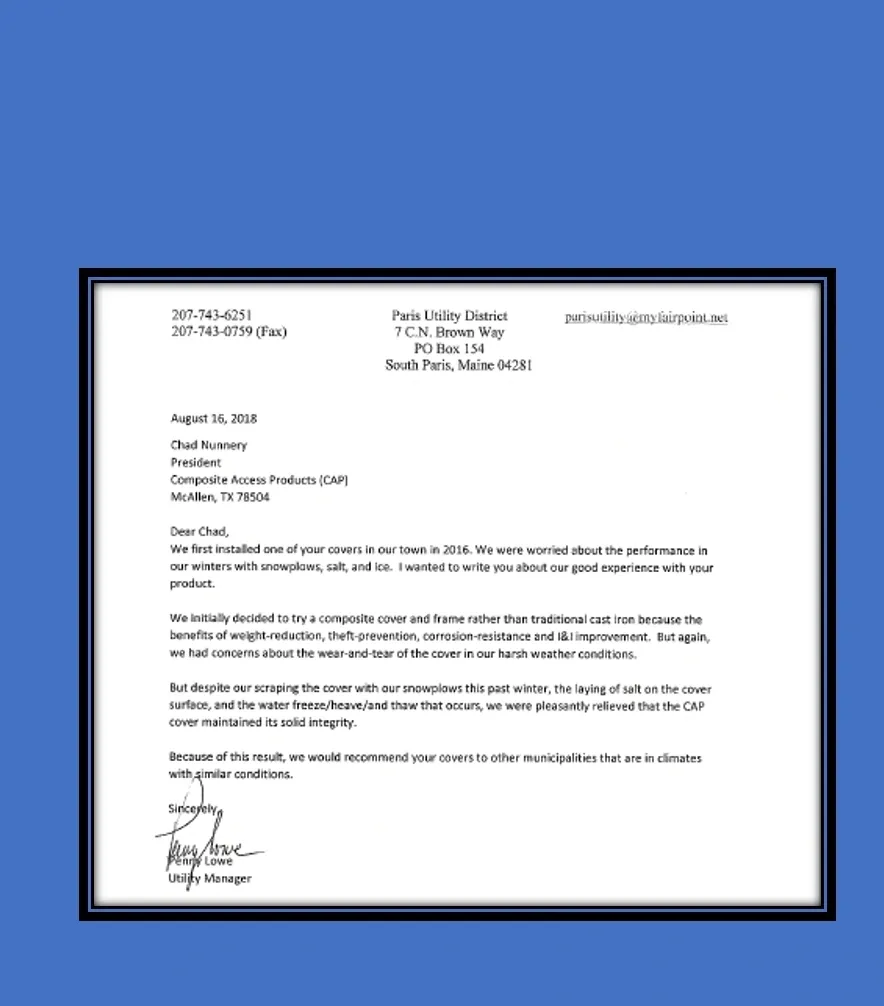

Minimal Wear Even Against Snowplows

Paris, Maine after 2 winters.

Cincinnati, Ohio after 5 winters

Director of Utilities in Maine Happy with Winter Performance

Snowplow Resistance

Minor wear to surface, but overall integrity maintained.

Salt and Snow – No Problem

Material did not corrode or degrade.

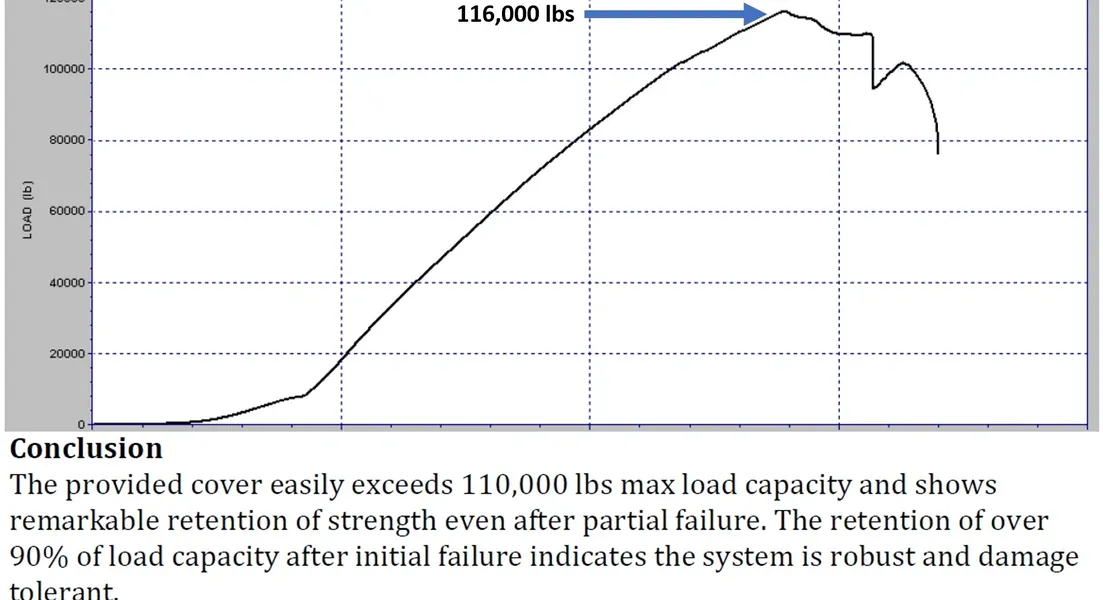

CAP ONE – 30 Cover Resists More than 115,000 lbs!

“Cover shows… remarkable retention of strength”

Because of the dramatic H-25 result, CAP decided to discover where the product would reach failure. Our CAP ONE 30, with a 32 inch span, reached 116,000 lbs of force on a 9-inch x 9-inch platen. This is like stacking more than two tractor trailers on top of each other and standing the bottom truck on one tire!

TXDOT Sends CAP Approval Letter

CAP Is The Only US Composite Manufacturer To Receive The Product Approval Letter by Texas Department of Transportation (TXDOT).

More Tests Results and Information Available

Request our Submission Package that contains all the information that your municipality or DOT would need for product evaluation.

Give us a call!

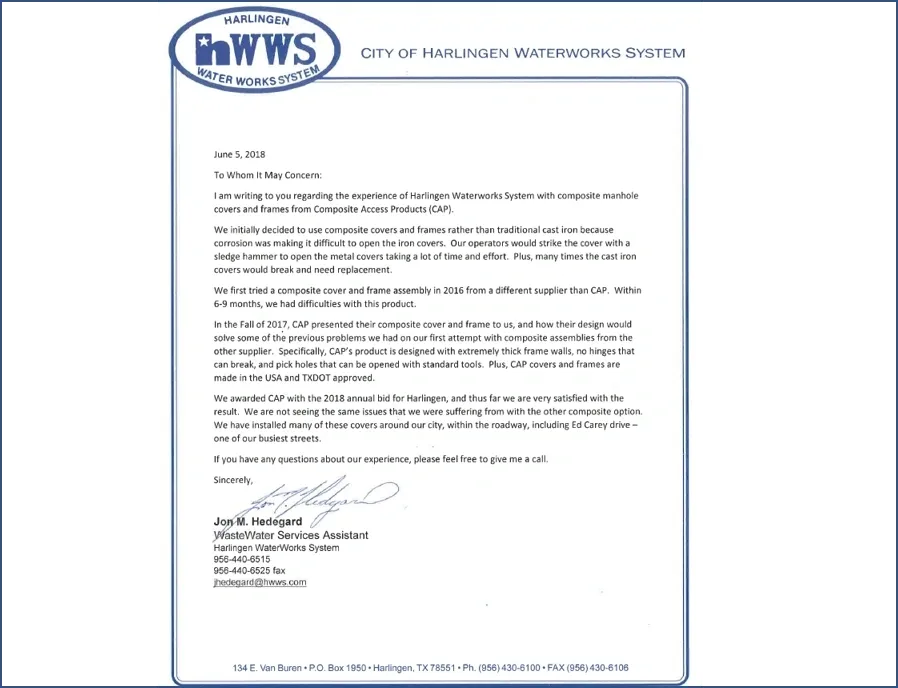

Another Customer Testimonial!

Municipal Water District Selects Composite

Corrosion drove the Harlingen Waterworks System (HWWS) team to a composite solution.

Water District Has Problems with First Try

HWWS first tried a composite import that presented several problems.

CAP Solves Problems with Superior Design

CAP’s thicker frame walls, larger flanges, thicker cover, and overall better design satisfied HWWS.

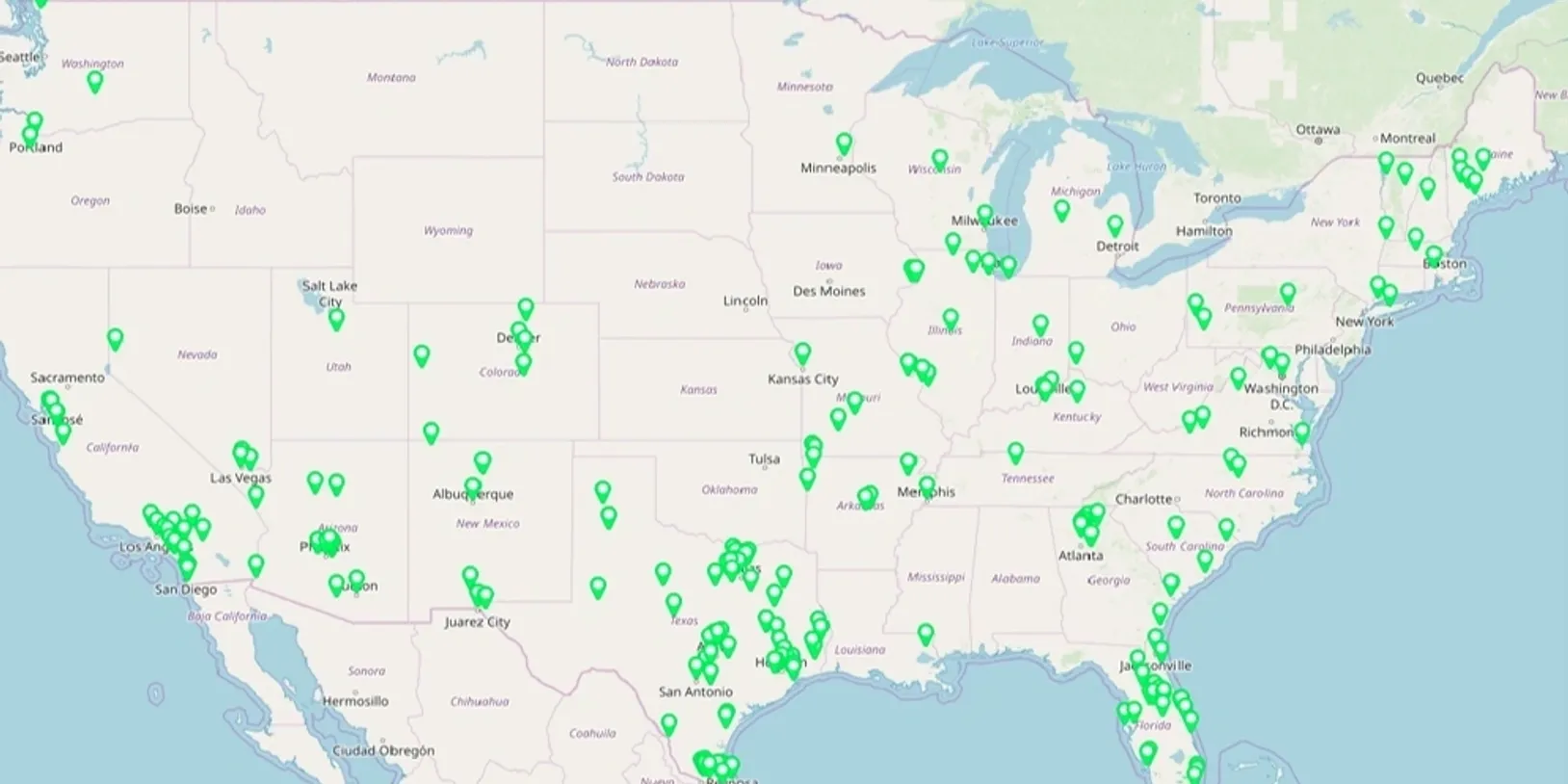

A Small Sample of Cities With CAP Covers

Harlingen, TX

San Juan, TX

Abilene, TX

Chandler, AZ

Brownsville, TX

Mesa, AZ

Fort Worth, TX

Alton, TX

Edinburg, TX

South Padre Island, TX

Corpus Christi, TX

Trinity River Authority (TRA)

Weslaco, TX

McAllen, TX

Trinity River Authority (TRA)

Cincinnati, OH

Guadalajara, MX

Guadalajara, MX

Many, many more CAPs