HALO™

Halo is the first-ever, patent-pending, traffic-rated composite top riser ring system for CAP Composite Manhole Covers. Raise manhole covers’ rim elevation before repaving in MINUTES.

No more digging, lifting, hauling, replacing, curing, and waiting, for under $500 per manhole.

CAP ONE® – 36

In the Spring of 2022, CAP will have a Made in the USA, 36-inch clear opening cover and frame assembly. It will be much more robust than those in the market today, and many more options. Plus logos!

CAP ONE® – 30

CAP ONE is our standard 30″ clear opening assembly for all cover markets: water, wastewater, electric, broadband, etc. The bottom text is just changed.

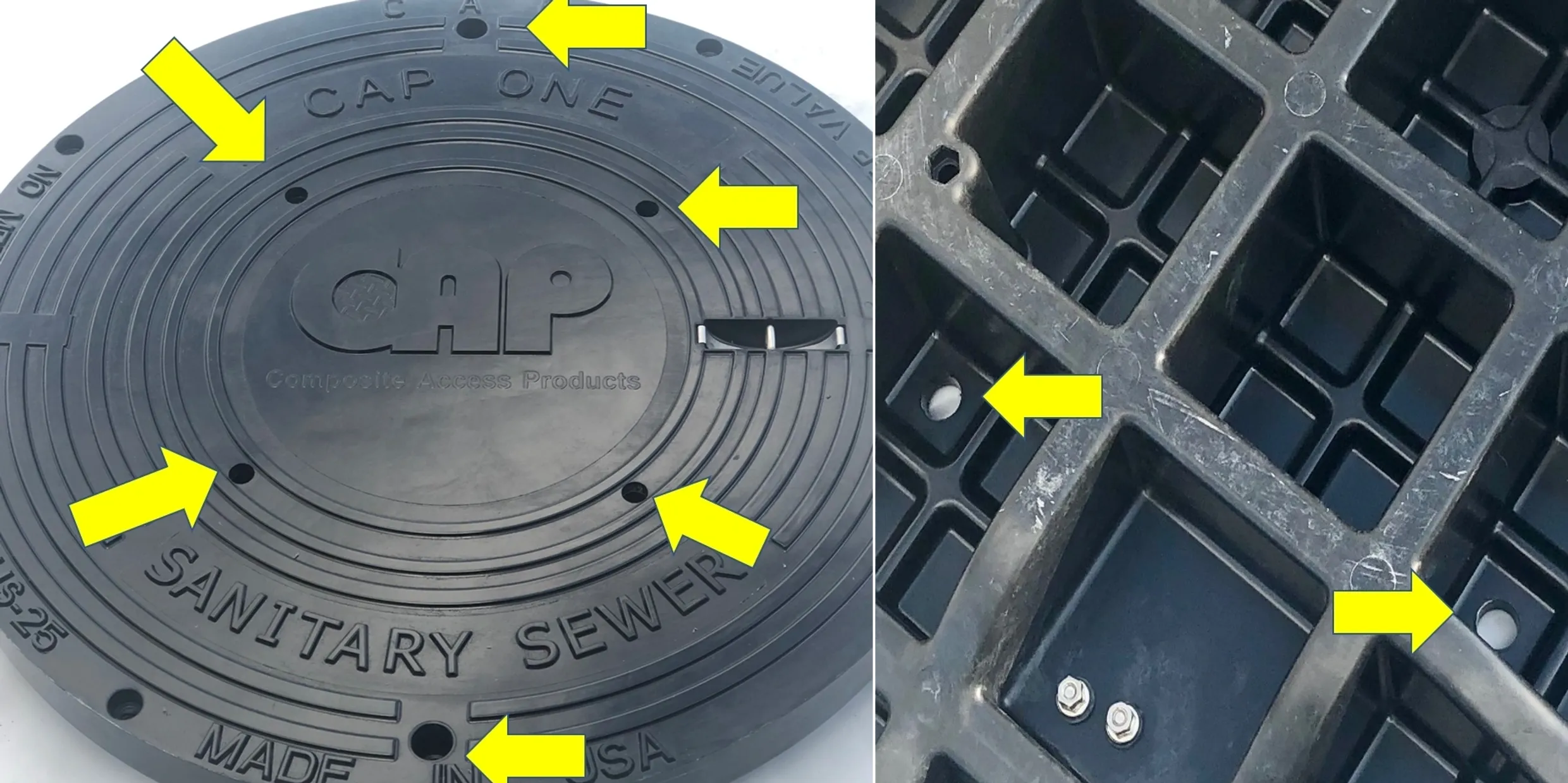

CAP ONE® – 24

With a 24-inch clear opening, the CAP ONE-24 is made with either bolts or quarter-turn paddle locks. Custom logos are available in the top arch, center circle, and bottom arch locations..

CAP CLAW™

The CAP CLAW is a dual function tool: 1. unbolt or unlatch with sockets 2. open, close and turn the cover with the pick hook…Ergonomic and fast!

CAP STONE™

CAP STONE products demonstrate another differentiating composite advantage from iron – blended stone hues – not just painted.

HALO

Complicated and expensive manhole cover elevation adjustments are no more, thanks to the Halo composite riser ring system exclusive to CAP products. With this new system, CAP brings the same advantages of their manhole covers to a new problem in road maintenance. Install in minutes, by a single person, and slash costs by up to $5,000 per manhole. The future of manhole covers is here.

Patent-Pending Technology

The Halo riser ring uses patent-pending technology, making it a unique solution in road maintenance. Our innovative design not only simplifies the installation process but also offers unmatched security and flexibility, setting it apart from anything else on the market.

Stackable For Future Repavings

The Halo is designed to be easily stackable, allowing you to add additional riser rings during future repaving projects without the need for excavation.

This feature saves $5,000 per manhole, making maintenance more cost-effective and efficient.

Easy to Install

The Halo is easy enough to handle for one worker. With ian nstallation that takes minutes, it reduces labor costs and speeds up the project, helping you finish faster and with less effort.

Watertight

The Halo Riser Ring System offers superior watertight protection, ensuring no infiltration or inflow into your infrastructure. Built to prevent water from entering, it keeps your systems dry and secure, even in the harshest conditions.

Corrosion Resistant

Made from durable composite materials, the Halo is highly corrosion-resistant. Unlike metal alternatives, it stands up to sewer gases like H2S, hydrogen sulfide, offering long-lasting performance without corrosion or degradation.

Cost Effective

Avoid unforeseen costs in future adjustments. While competitors’ covers may appear less expensive, they incur an extra $5K-$10K per cover for overlays. Opt for CAP from the start to avoid these costs and secure savings.

CAP ONE – 36 …”THE BEAST”

Bigger & Bolder – 100K+ Lb Load Rating!

CAP’s newest cover boasts a 41 ” diameter and 2 inches of thickness. CAP, once again, makes the “tank” of the composite manhole covers. Lighter than iron, but still rugged. H-25 traffic rating!

Sturdy, Stout, Solid, Substantial

Longer flanges, thicker walls, twice the frame ledge, and more than 3x the materials used, CAP gives confidence that this is a “real” manhole cover. The CAP ONE -36 frame gives 36 inches of opening.

Watertight! Stop I&I!

Submerged in 15 inches of water, overnight, with 0.00 gpm through the cover & frame. Perhaps the only 36-inch clear-opening, watertight cover with accessories included standard.

CAP ONE Features

Corrosion-Resistant Hardware

CAP locking systems and hardware exposed to H2S gas are made with 316 Stainless Steel – Austenite crystal, giving maximum resistance of a metal to corrosion. Also, CAP’s bolts are all Xylan-coated to prevent galling and stripping. CAP offers three bolt head types: hex, allen, and penta. Special, unique key heads are also available. Don’t like bolts? CAP also offers 316 SS “Paddle Lock” latches for faster access (see below)

Thicker Frame Walls

Compared to another composite option, CAP’s frames (top frame in photo) have twice the wall thickness and twice the flange. This provides adequate robustness for vehicle impact and other common handling abuse.

Watertight…or Vented!

Vented CAPs with Molded-In (Not Drilled) Holes!

If you don’t need our watertight version of the CAP ONE, and need to release line pressure, CAP can mold-in vent holes…not drilled holes! Drilling can expose fiber filaments to the environment. And CAP’s vent holes are not on the structural members (photo on right). Molding-in holes is impossible or difficult to do with other composite options. For example, in the Resin Transfer Molding (RTM) process, the manufacturer must stack many layers of woven fiber. Molding holes in RTM covers would require holes cut into the raw materials, so holes are drilled into post-molded covers in many RTM solutions rather than molded-in.

Why Choose CAP Products?

Molded in Texas, USA

Concerned about sending tax-payer funds to foreign manufacturers? Desire trace-ability to raw materials and local support? Contact us for a facility visit.

TX DOT Approved

The Texas Department of Transportation (TXDOT) sent CAP the letter formally approving composite covers in TXDOT infrastructure and right-of-way in August ’17.

Rapid Compression Molding

Compression molding improves cost & lead times with rapid production vs. the less efficient, higher cost, Resin Transfer Molding (RTM). Call your distributor to stock-up!

Molded-In Colors

Interested in differentiating your wastewater, storm water, and other utility lines with a quick visual – perhaps colors will help.

Fastener Options – Xylan Coated, 316 SS

CAP understands each municipality has its preferred tool. Choose your fastener head(Hex, Allen, Penta) for bolted or quarter-turn models.

Molded-In Logos

Are custom logos important to your city, business, campus, or other organization? CAP can create the tooling for your look.

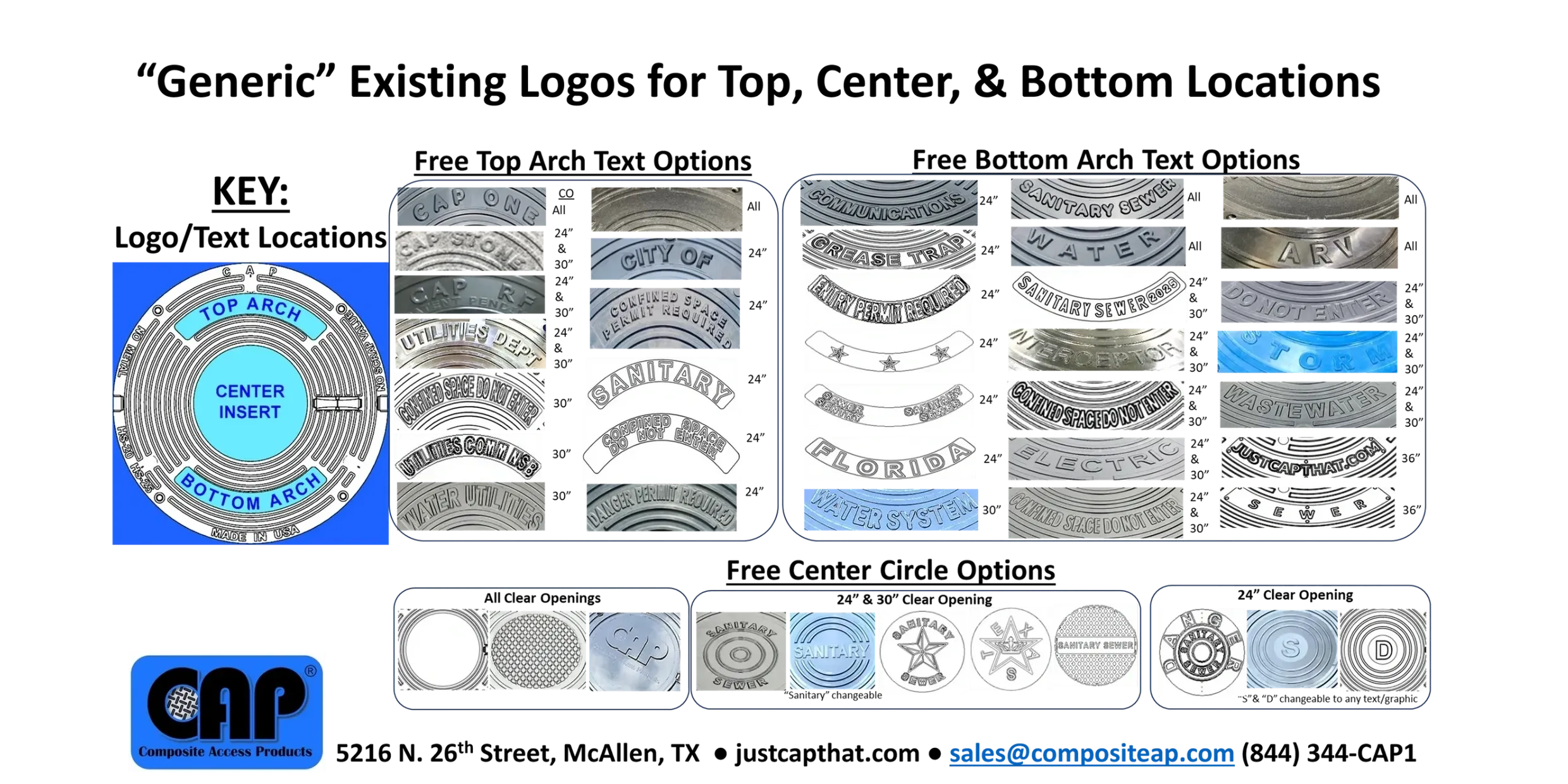

Custom Logos and Text!

Existing Message Or New Ones

CAPs have three custom message, text, and graphic areas. The top arch is typically used to identify the municipality name, the center circle is used for a graphic, and the bottom arch usually is used for the utility type. Many “generic” message molds have already been created and can save the one-time setup fees.

Want Your Logo – Send Us The Detail

CAP can produce interchangeable, hardened steel

molds for the custom logo positions. These molds can

withstand 800 tons and look sharp! So, CAP logos are

molded in the substrate – not a surface decal or veil.

CAP logos are 3-4 times deeper (about 1/8 inch) on

the surface vs. some current RTM options. CAP logo

depth gives a more pronounced surface appearance.

RTM detail as deep as CAP would create resin-rich

areas that can blister and wear – one reason some RTM

covers have 0.03″ to 0.04″ tread depth.

CAP Patented Innovation: Detecting Nonmetallic Covers

CAP’s Solution (Video Above): How to Detect Buried/Overlaid Covers w/o Detectable Metal?

CAP’s patented innovation allows for the metal detection of CAP covers using common metal detectors, without adding metal to the CAP or using corrosion-prone metal fasteners. Detectable metal (non-stainless) mounted on a cover exterior will corrode over time, and CAP products do not require any exterior ferrous attachments.

The video shows a CAP cover detected under 12 inches of dirt. This innovation is standard for CAP products — and only CAP offers this technology.

Video: Quick In-and-Out Paddle Lock Option

CAP composite covers have three fastener options: 1. bolted covers-best watertight & odor containing seal 2.”Stiff” paddle locks -for sandy areas 3. “Spring” paddle locks allows – for a “burp” or pressure relief avoiding cover dislodge. This video shows opening the “Spring” paddle lock. CAP offers a menu of hardware head types: 1. Hex, 2. Penta, 3. Allen, 4. Special Key. Click “Play” arrow to see the video.

Video: Opening the “Stiff” Paddle Lock Option

Easy Opening Cover – Video

CAP covers are lighter than iron…but NOT too light! Manhole covers were not meant to be Frisbees (Frisbees fly). This video demonstrates an alternate method to open a CAP™ with the new “CAP CLAW.”Click “Play” arrow to see the video.

Instructions, Drawings, Letters, Specification

Attached are only some of the downloadable documents. Contact us for test results and other submission data needed.

CAP BABA Manufacturer Certification 12-12-24 (pdf)

Cut Sheet Drawing Request Form RV08272025 (pdf)

TXDOT Approval Letter 12-2022 Ref#16-2979 (pdf)

Installation Guide and Detail for CAP Composite Cover and Frames RV061623 (pdf)

HALO Installation Instructions Rev07 (pdf)

CAP ONE-36 Product Code A-1BK36N4-C01DMDSS-H2 (pdf)

CAP ONE-30, 2-Paddle Locks, Stnd Arch Logos – Sanitary, Diamond – Blank Center logo (pdf)

CAP ONE-30, 2-Paddle Locks, Stnd Logos – Sanitary – Vented (pdf)

CAP ONE-24, Bolts, Diamond Blank Ctr, Sanitary (pdf)

CAP ONE-24, Bolts, Stnd Logos, Sanitary (pdf)

CAP ONE-24, Bolts, Diamond Blank Ctr, Storm (pdf)

CAP ONE 30 four Allen head bolts with standard logos, sanitary sewer (pdf)

CAP ONE – 30 with Allen bolts, CAP ONE top arch, diamond (pdf)

CAP ONE – 30 with Allen Paddle Lock, CAP ONE top arch, CAP Logo center, sanitary sewer (pdf)

CAP – limited Warranty – 5-2023 (pdf)